The Glazed Tile Roll Forming Machine is designed to produce high-quality, decorative, and durable glazed roofing tiles, often used for residential, commercial, and industrial buildings. This machine is specifically engineered to transform steel coils into beautiful, traditional-looking glazed tiles, mimicking the appearance of ceramic or clay tiles while offering the superior strength and weather resistance of metal. It is widely used in roofing projects, offering both aesthetic appeal and excellent functionality.

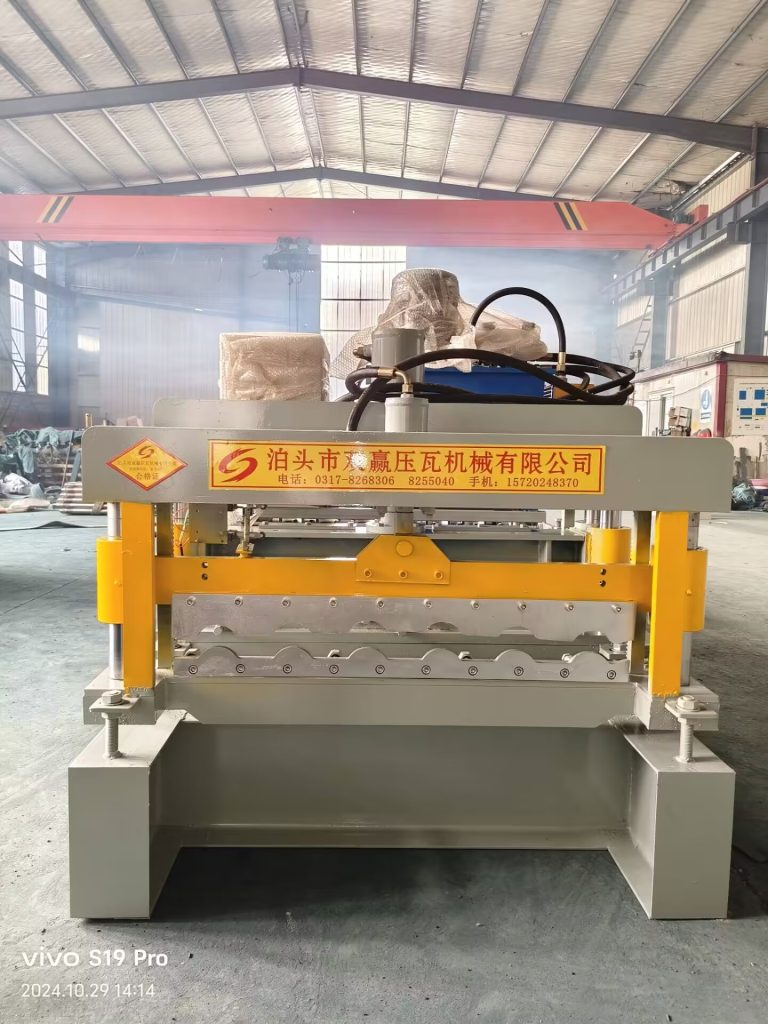

Glazed Tile Roll Forming Machine

The Glazed Tile Roll Forming Machine is designed to produce high-quality, decorative, and durable glazed roofing tiles, often used for residential, commercial, and industrial buildings. This machine is specifically engineered to transform steel coils into beautiful, traditional-looking glazed tiles, mimicking the appearance of ceramic or clay tiles while offering the superior strength and weather resistance of metal. It is widely used in roofing projects, offering both aesthetic appeal and excellent functionality.

Key Features and Functions:

- Material Compatibility:

- The machine processes materials like pre-painted steel, galvanized steel, or aluminum coils, converting them into stylish and weather-resistant glazed tiles.

- Roll Forming Technology:

- Steel coils are fed through a series of precision rollers that gradually form the desired glazed tile profile. The rollers shape the steel into a tile pattern that mimics the traditional look of clay or ceramic tiles.

- Automatic Cutting System:

- The cutting system is synchronized with the roll forming process. Once the tile reaches the required length, the system automatically cuts the tile to the correct size.

- Customizable Profiles:

- The machine can be adjusted to produce different types of glazed tile profiles, depending on customer needs. The profiles can vary in size and shape, offering flexibility for different building styles.

- High Production Efficiency:

- The machine operates at high speeds (typically 8-12 meters per minute) and provides consistent results, making it ideal for large-scale production of glazed tiles.

- Durability and Corrosion Resistance:

- The tiles produced are highly durable, resistant to corrosion, and capable of withstanding harsh weather conditions, offering long-term protection for buildings.

- Energy Efficient:

- The glazed tile machine is designed to optimize energy consumption while maintaining a high production rate, offering significant cost savings in the long run.

- Advanced Control System:

- The machine is typically equipped with a PLC control system, allowing for easy operation and efficient switching between different profiles, as well as precise control over all production parameters.

Performance Parameters:

- Material Thickness:

Typically 0.3 mm – 0.8 mm (can vary depending on the type of material and profile). - Tile Width:

Generally ranges from 300 mm to 1200 mm depending on the profile. - Production Speed:

Typically 8-12 meters per minute, depending on the material and profile complexity. - Forming Rollers:

Typically has 12-18 rollers, depending on the desired profile and machine configuration. - Cutting Method:

Hydraulic or mechanical cutting, synchronized with the forming process to ensure accurate panel lengths. - Control System:

PLC (Programmable Logic Controller) for easy operation and profile adjustments. - Power Supply:

Typically 380V, 50Hz, but can be customized based on regional voltage requirements. - Weight and Dimensions:

The weight and dimensions vary depending on the machine size and configuration, typically ranging from 5 tons to 12 tons.

Advantages of the Glazed Tile Roll Forming Machine:

- Aesthetic Appeal:

Produces roof tiles that have the traditional, attractive look of clay or ceramic tiles, but with the added strength and durability of metal. - Weather Resistance:

The tiles are resistant to harsh weather conditions, including rain, snow, and UV radiation, making them a reliable option for long-lasting roofing. - Cost-Effective:

The machine offers a more affordable alternative to ceramic and clay tiles, providing better value without sacrificing quality. - Energy-Efficient:

Designed to reduce energy consumption while maintaining high production output. - Easy Maintenance:

The machine is built for durability and requires minimal maintenance, making it a long-term investment for manufacturers. - Customizable Profiles:

Offers flexibility in the type of glazed tile profiles, making it suitable for various architectural styles.

Applications:

- Residential Roofing:

Ideal for use in residential homes, providing a beautiful and durable roofing solution that mimics traditional ceramic tiles. - Commercial and Industrial Buildings:

Suitable for both commercial and industrial buildings where a durable and aesthetically pleasing roofing option is needed. - Restoration Projects:

Perfect for restoring historical buildings, as the tiles provide a traditional appearance with modern material benefits.

Example Configuration:

- Material Thickness: 0.3 mm – 0.8 mm

- Tile Width: 1000 mm

- Production Speed: 10 meters/min

- Tile Length: Adjustable (typically up to 6 meters)

- Rollers: 12-16 rollers

- Cutting Method: Hydraulic cutting

- Power: 5.5-7.5 kW

Contact Us:

For more information or to request a quote, please contact:

- Whatsapp: +8613832784260

- Email: zhaohuabb@163.com

- Company: China Botou Win-Win Roll Forming Machine Co., Ltd.

| Specification | Details |

|---|---|

| Product Name | Color Steel Tile Press Machine |

| Brand | Win-Win |

| Frame Material | 400H Steel |

| Drive Power | 3-5.5 kW |

| Transmission Method | Chain |

| Chain Size | 1 inch – 1.2 inches |

| Shaft Diameter | 70 mm |

| Shaft Material | 45# Steel Tempered |

| Wheel Material | 45# Steel Hardened Chrome |

| Side Plate Thickness | 14 mm |

| Hydraulic Power | 3-5.5 kW |

| Hydraulic Method | Gear Pump |

| Tile Output Speed | 8-12 meters per minute |

| Feeding Width | 750-1250 mm |

| Machine Dimensions (LWH) | 5000 x 1400 x 1200 mm |

| Weight | 2-5 tons |

| Unit Price | 8000-15000 USD |

| Model | 820 Type, 840 Type,820type,900type,1000type |